- www.beissermetall.de / Home / Sheet metal processing / Our machinery

Machinery

Highly-motivated and highly-trained staff are an important part of the long success story of BEISSERMETALL. A further factor in our success if, however, continuous investment in new manufacturing technology because only by continuously developing and optimising everything involved in the process, both humans and machines, can we achieve the results that our customers expect from us and that they receive.

Detailed information about our metal sheet processing machinery can be found here.

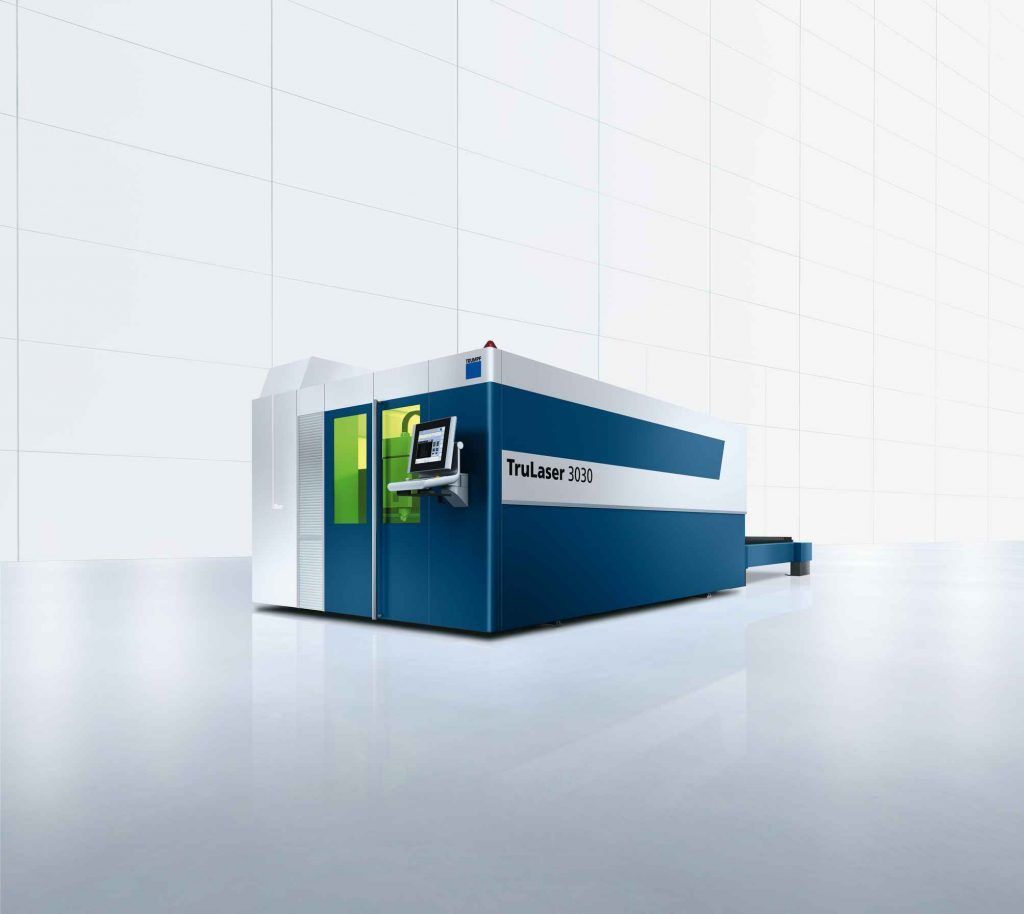

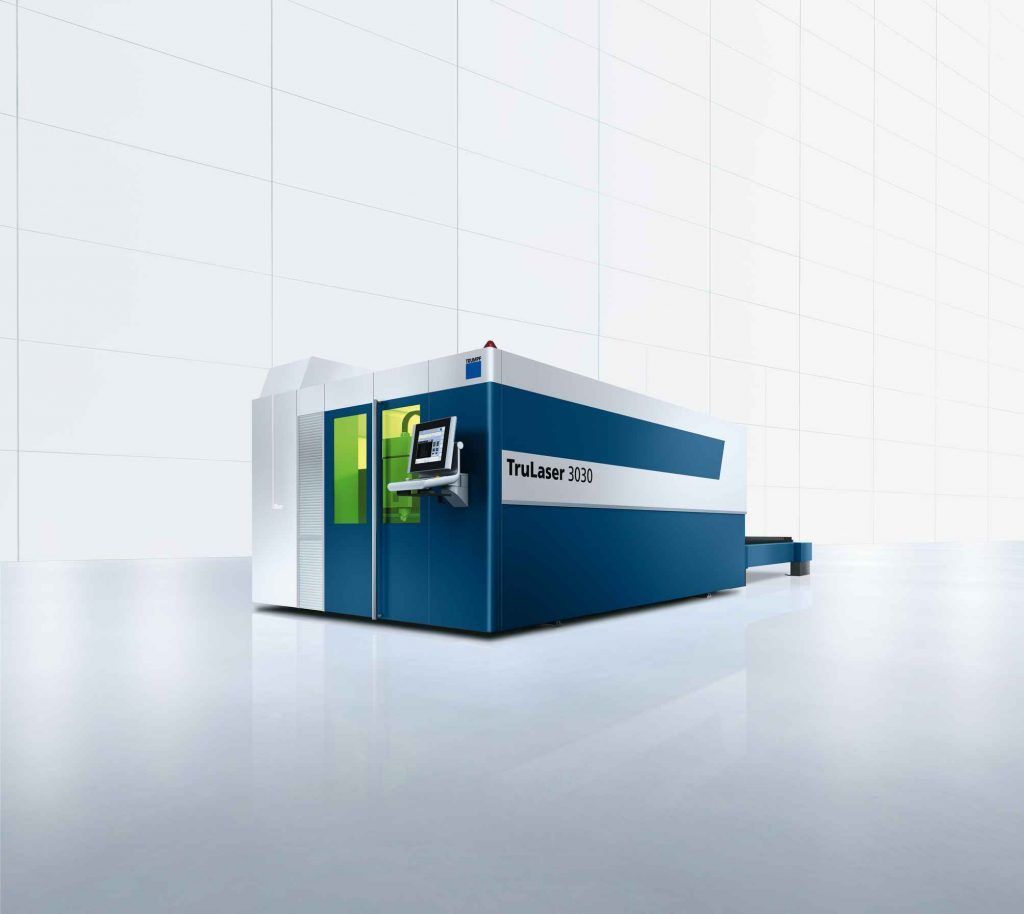

Laser

With our new Trumpf Trumatik L 3030 laser cutting system we have once again significantly increased our sheet metal processing capability.

Sheet size:

3000 x 1500 mm

Mild steel:

up to max. 20 mm material thickness

Stainless steel:

up to max. 15 mm material thickness

Aluminium:

up to max. 10 mm material thickness

We can also carry out all follow-on work, such as folding, edging, seal welding, point welding, riveting and joining for you.

Laser welding machine ALFlak 300

Average power: 300 W

Pulse peak power: 9 kW

Pulse energy: 90 J

Pulse frequency: single pulse: 100 Hz (in automatic mode and under observation)

Pulse duration: 0.5 ms – 20 ms

Welding spot Ø Focusing lens: 0.5 – 2.0 mm

Pulse shaping: Adjustability of the power curve within a laser pulse

Control: user-specific operation, up to 39 parameter sets

Observation optics: Leica binocular with eyepieces for spectacle wearers

X, Y, Z in mm: 1500 x 1000 x 1000

Travel range (X, Y, Z) in mm: 340 x 320 x 420

Lowest operating point in mm: 200

Highest operating point in mm: 1500

Arm deflection/working distance (mm): 1500

LxWxH Base part in mm: approx. 1200 x 1200 x 1100

Weight: with crawler chassis 850 kg – without crawler chassis 550 kg

Electrical connection: 3 x 400 V / 50-60 Hz / 3 x 16 A

Due to the possibility to move the workpieces, we are also able to offer you large components.

Press brakes

For folding or edging, the following press brakes are used:

CNC press brakes from Weinbrenner

Folding length 3000 mm

TrumaBend press brake with 3D graphical control and ACB angle sensor from Trumpf

Folding length 2050 mm

Press-in machine

Pressure range:

250 to 16,000 reads (1kN – 72kN) optional 20,000 lbs. (90kN) modification available.

Design:

24″ (610 mm)

Maximum stroke:

0 to 8.0″ (0 to 220mm) up to 2000 pressings per hour

Pressure tolerance:

+/-2% of the set pressure

Space requirement:

– (LxWxH) 59″ x 38″ x 94″ (1499mm x 966mm x 2388mm)

Dimensions of the press-fit elements:

256 to 1/2″ (M2 to M12)